Inquiries Concerning News

Corporate Communications Div.,

The Mitsubishi Chemical Group

TEL: +81-3-6748-7140

Mitsubishi Plastics develops a high heat-resistant separator

Dec. 16, 2011

Mitsubishi Plastics, Inc. (head office: Chuo-ku, Tokyo; President Hiroshi Yoshida) has developed a cost-competitive, high heat-resistant separator, targeting the lithium-ion secondary battery market for electric vehicles (EVs), where increased demand for the product is expected. Mitsubishi Plastics will have the separator undergo quality testing by manufactures of lithium-ion secondary batteries for EVs prior to its launch in 2012. Mass production will start by 2013.

The separator for lithium-ion secondary batteries developed and manufactured by Mitsubishi Plastics is one of the four key components in the lithium-ion battery materials business, which is regarded as a “growth business” field by the parent company Mitsubishi Chemical Holdings. It is a porous film that allows the proper amount of lithium ions to pass through but prevents electrical shorts caused by the cathode coming into contact with the anode. The film also has a shutdown function as a safety switch in case of thermal runaway by closing the pores of the separator.

Since fiscal 2010, there has been an increasing demand for separators for EV batteries, which are expected to account for around 40% of the market share by 2015 (as estimated by the Company). There are roughly two processes for methods of manufacturing separators: dry and wet. The dry process is expected to become widely used to produce separators for EV batteries as this method offers cost competitiveness and produce separators suited to high power out put. Meanwhile, with the increasing popularization of EVs, separator manufacturers will be urged to develop new types of them that can offer enhanced cost competitiveness as well as higher heat resistance that promises greater safety.

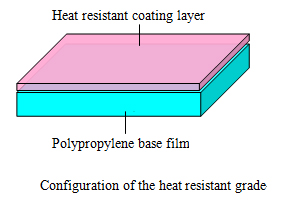

In 2009, Mitsubishi Plastics has developed SEPALENTTM, a lithium-ion secondary battery separator made through its unique dry process. This project has been carried out in collaboration with Mitsubishi Chemical Corporation, the group company engaged in production and distribution of lithium-ion secondary battery materials. SEPALENTTM is a highly-functional separator developed by making use of various technologies the Company has developed over the years including its material design technology and film-forming technology. Because of a high level control of porous structure, SEPALENTTM, which is produced through a dry process, has a porous structure similar to that of the separators made through wet process. This gives SEPALENTTM positive traits of batteries such as low-temperature output property and cycle life. Mitsubishi Plastics started full-fledged sales of SEPALENTTM in 2011 to some domestic and overseas companies: the results are very encouraging, indicating that the demand is set to increase further. Accordingly, another new production line is currently under construction. In addition to this, Mitsubishi Plastics has recently developed the cost competitive, high heat-resistant separator, targeting the EV lithium-ion secondary battery market, where increasing demand for separators of this kind is expected going forward. By applying its unique technology of heat resistant coating to its existing separator model, Mitsubishi Plastics has successfully produced the new separator with a high heat resistance over 200 degrees Celsius, which helps prevent an internal short circuit of batteries. Furthermore, the Company’s coating agent development capability and coating process technology accumulated over the years equip the new separator with superior cost competitiveness to other heat-resistant separators (made through a wet method) on the market.

The Company plans to launch sales of the high heat-resistant separator in 2012, making joint effort with Mitsubishi Chemical Corporation which sells four materials of lithium-ion secondary batteries including separators. In so doing, the Company conducts product specification verification activities targeting the global EV battery market, while having the product undergo performance evaluation and customization of the product for each manufacturing customer. Mass production of the separator is planned to starting in fiscal 2013, with a sales goal of 72 million square meters of separators (all types) in fiscal 2015.

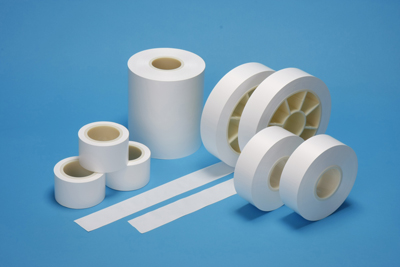

SEPALENT TM a separator for lithium-ion secondary batteries

Inquiries by media regarding this material should be directed to the

Public Relations Section, General Administration Dept., Mitsubishi Plastics Inc.

TEL: +81-3-3279-3800