Inquiries Concerning News

Corporate Communications Div.,

The Mitsubishi Chemical Group

TEL: +81-3-6748-7140

Expanding Production Capacity for Lithium-ion Secondary Battery Separators

Aug. 31, 2011

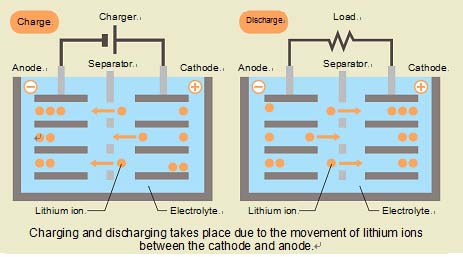

Mitsubishi Plastics’ Sepalent™ is a highly-functional separator developed by making use of the various technologies the Company has developed over many years including its material design technology and film-forming technology. Although a dry battery, it possesses a porous structure that is similar to that of a wet battery due to the control of its porous structure. The separator is characterized by various traits of batteries including low-temperature output and cycle life.

Mitsubishi Plastics constructed production facilities (annual capacity of 12 million m2) to mass produce Sepalent™ at its Nagahama Plant in 2009 and conducted test sales. Since then Sepalent™ has received high praise from customers and has been adopted for use in lithium batteries for various purposes such as mobile phones, power tools, and laptop computers. Since demand is expected to continue to grow, Mitsubishi Plastics decided to construct a new production line with an annual capacity of 15 million m2. The new line is expected to be completed in the summer of 2012.

Mitsubishi Plastics will continue to deepen its alliance with Mitsubishi Chemical Corporation, which involves various activities including sales; move forward with developing advanced separators that meet the needs of customers, such as making them heat resistant, which is necessary if they are to be used for hybrid cars and electric vehicles; and actively strive to help the Mitsubishi Chemical Holdings Group expand its lithium-ion secondary battery material business. In addition, Mitsubishi Plastics will keep an eye on demand and supply trends in the market and examine expanding production capacity further as necessary.

|

■Inquires regarding this material should be directed to the |

|

|

Public Relations Section, General Administration Dept., TEL: +81-3-3279-3800 |

|