Inquiries Concerning News

Corporate Communications Div.,

The Mitsubishi Chemical Group

TEL: +81-3-6748-7140

New Urethane Composite Panel for Truck Chassis -Meets Needs for Wood-free, More Lightweight Chassis-

Dec. 21, 2009

|

Mitsubishi Plastics, Inc. (head office: Chuo-ku, Tokyo; president: Hiroshi Yoshida) has developed ALPOLIC™ DB and ALPOLIC™ DB Light, which consist of rigid urethane foam sandwiched by ALPOLIC™. The two new products expand the ALPOLIC™ lineup of aluminum/plastic composite panel, which is used around the world as an interior and exterior construction material, into the truck market. MPI will launch sales in January 2010. |

ALPOLIC™ DB Light and ALPOLIC™ DB |

ALPOLIC™ is a multilayer aluminum/plastic composite panel that first went on sale in 1974. It is made from a polyethylene core, sandwiched by two sheets of aluminum. This three-layer construction makes ALPOLIC™ lightweight and rigid, easy to work, and gives it high surface smoothness (good aesthetic quality). It is used as a construction material in about 130 countries worldwide. MPI began to market ALPOLIC™ as a chassis (auto body) material several years ago as part of its initiative to expand the applications of this product. ALPOLIC™'s light weight, surface flatness, and excellent sanitation have won it acclaim, and its use is gradually expanding.

The new products were developed as a new panel material meeting the needs for a lighter material that does not use wood, with the aim of expanding the ALPOLIC™ business in the truck market. MPI will launch sales of two new products: ALPOLIC™ DB, which uses a layer of rigid low-foam urethane sandwiched by ALPOLIC™; and ALPOLICDB Light, consisting of a layer of high-foam urethane sandwiched by ALPOLIC™, which is lightweight and has good insulation properties.

ALPOLIC™ DB is lighter than conventional composite panels consisting of wood (MDF) and aluminum, and it does not rot. This enables the material to be used hygienically for long periods. The use of low-foam urethane also gives it excellent rigidity, making it easy to work with: it can be installed in any location using just bolts and screws. This is perfect for the rear doors of trucks, which use many bolts and other fastenings. Thicknesses of 13 to 19 mm can be provided.

ALPOLIC™ DB Light is panel made with high-foam urethane, with a thickness of 13 mm or more. This ultra-lightweight, woodless, highly insulating panel is perfect for freezer or refrigerated trucks requiring high insulation, as well as the sliding doors and other components of trucks that transport beverages (vending cars).

The thickness, color, surface finish, and other aspects of each product are order made to suit the customer's needs.

The new products are already in use on a trial basis in the sliding and rear doors of some vending cars, and after seeing their great popularity, MPI has decided to launch full-scale sales. MPI will promote the products widely, including to truck manufacturers (especially manufacturers of truck bodies), logistics companies, and food manufacturers who ship cargo, beverage manufacturers, and others, and it will focus on expanding sales to these markets.

●Products in trial use in truck body (18 mm DB Light on sides, 13 mm DB in rear)

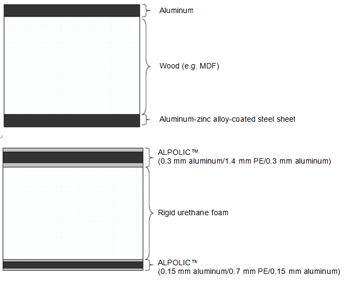

●Construction Conventional Product (top) and ALPOLIC™ DB (bottom)

(Construction of conventional product is representative example)

|

■Inquires regarding this material should be directed to the |

|

|

Public Relations Section, General Administration Dept., TEL: +81-3-3279-3800 |

|