Inquiries Concerning News

Corporate Communications Div.,

The Mitsubishi Chemical Group

TEL: +81-3-6748-7140

MPI Develops New Technology for Creating High Quality Cast Aluminum Alloy Products

Aug. 5, 2009

Mitsubishi Plastics, Inc. (head office: Chuo-ku, Tokyo; president: Hiroshi Yoshida) has developed a special continuously casting technology, that create a fine and uniform metal structure in the microstructure of aluminum ingots. It has created ALFINE™ high-quality aluminum ingots using this new technology, and will launch sales on August 10th.

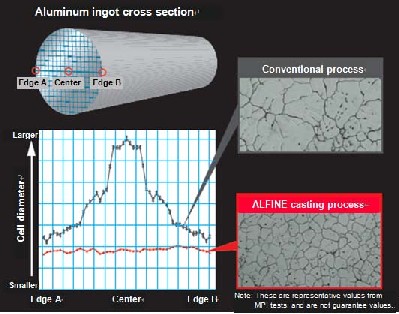

MPI performs every aspect of the aluminum-production process, from casting to processed products, including the manufacture and sale of aluminum alloys (billets and slabs), die-cast materials, and extruded materials. Drawing on the technical knowledge of aluminum casting accumulated over many years, MPI has developed a special casting technology for manufacturing aluminum ingots with uniform microstructure from the surface to the center. ALFINE™ aluminum ingots are made using this new technology. The basic physical properties of ALFINE™ aluminum ingots are dramatically better than conventional aluminum ingots, and MPI expects them to provide excellent properties for a wide range of applications, including casting and machined materials.

For example, when a billet made using this new technology is cast via cold-work, it can provide excellent properties compared to conventional billets, even at low forging ratios. It can also be produced with fewer processes, which should reduce processing costs. Its low deformation resistance also makes it easier to form, enabling complex shapes to be formed that would not be feasible with conventional materials. This should greatly expand the scope of casting design.

ALFINE™'s finer microstructure also makes slabs and other machined and cut materials easier to cut. It also greatly reduces uneven anodization in 5,000 series aluminum alloy*, which should make it usable for a wide range of cutting and machining applications.

MPI will position ALFINE™ aluminum ingots made with this new casting technology as a central pillar of its casting business, as an aluminum ingot with higher quality than conventional products. It is aiming for net sales of ¥2 billion after three years (FY 2012), by offering a wide range of applications in response to customer needs.

* This is an alloy made by adding magnesium to aluminum. Its good balance of mechanical properties make it widely used in automotive chassis and other applications.

Features of ALFINE™ Uniform Microstructure Aluminum Ingots

1. Uniform crystal microstructure

2. Low deformation resistance

3. High toughness (stretch)

4. Few internal defects (e.g. honeycombs)

|

|

|

| Aluminum alloy billet | Aluminum alloy slab |

●Cell diameter distribution

|

■Inquires regarding this material should be directed to the |

|

|

Public Relations Section, General Administration Dept., TEL: +81-3-3279-3800 |

|