|

|

|

|

|

|

|

|

| July 14, 2016 |

|

Mitsubishi Chemical and Mitsui Zosen Machinery & Service to Form Tie-up

to Produce and Sell Zeolite Membranes

|

|

Mitsubishi Chemical Corporation

Mitsui Engineering & Shipbuilding Co., Ltd.

Mitsui Zosen Machinery & Service, Inc.

Mitsubishi Chemical Corporation (MCC; Head office: Chiyoda-ku, Tokyo; President: Hiroaki Ishizuka) and Mitsui Zosen Machinery & Service, Inc. (MZM; Head office: Chuo-ku, Tokyo; President: Masao Morita), a subsidiary of Mitsui Engineering & Shipbuilding Co., Ltd. (Head office: Chiyoda-ku, Tokyo; President: Takao Tanaka) have agreed to form a business tie-up to produce and sell zeolite membranes.

With the goal of entering new markets and expanding sales, MCC will purchase MZM's entire output of zeolite membranes and hold the sole sales rights in the U.S. and other global markets. Their agreement also provides proposals for new dehydration processes that will draw upon both companies' technologies.

[Background and objectives of business tie-up]

Bioethanol, which is made mostly from corn and sugar cane, has come into widespread use as a fuel all over the world, especially in the U.S. and Brazil, in step with efforts to reduce CO2 emissions and promote the carbon neutral movement. In particular, the U.S. now has more than 210 bioethanol plants in operation, backed by increasing demand as a gasoline additive. The U.S. Energy Independence and Security Act of 2007 (EISA) mandates doubling of current renewable fuels production by 2022.

In bioethanol refining and water removal processes, the pressure swing adsorption (PSA) dehydration process is used following the distillation process. The PSA process uses pellet-form general-purpose zeolite to remove water. Many plants adopted the PSA process more than 10 years ago, and will need bed refurbishment in the next several years.

In addition, the U.S. Environmental Protection Agency (EPA) is aggressively encouraging ethanol producers to make production process more energy efficient and requires ethanol derived from corn starch to meet a 20% lifecycle GHG reduction threshold. To meet that requirement many producers have started installing energy-saving equipment and processes as they gear up to increase production, and that will require ZEBREX™ or similar energy efficient technologies.

MZM has produced and marketed A-type zeolite membranes since 1998, and its products have been adopted in over 70 plants. Due to A-type zeolite membrane’s strong dehydration performance, it has been adopted in industrial alcohol solvent collection systems and bioethanol water-removal processes.

MCC successfully developed its unique CHA-type zeolite membranes, which have superior resistance to water and acid. They have been adopted in the solvent collection system developed by Mitsubishi Chemical Engineering Corporation (MEC, Head office: Chuo-ku, Tokyo; President: Ryuji Fukumura) and in Japanese sake concentration, which requires both water resistance and acid resistance.

MCC and MZM have already started joint marketing of a dehydration system using ZEBREXTM zeolite membranes in combination with A-type zeolite membranes and MCC-developed CHA-type zeolite membranes for bioethanol production processes in the U.S., along with Taiyo Nippon Sanso Corporation (TNSC; Head office: Shinagawa-ku, Tokyo; President: Yujiro Ichihara). The new business tie-up will help MCC and MZM further expand the zeolite business by taking advantage of MCC’s zeolite development technology, the Mitsubishi Chemical Holdings Group’s marketing capabilities, and MZM’s A-type zeolite production technology and the product recognition.

[Details of business tie-up]

(1) Marketing and sales of A-type zeolite membranes

MZM will produce A-type zeolite membranes, and MCC will market them exclusively. MCC is engaged in marketing and new business development for A-type zeolite membranes with MZM's support.

In the U.S. market, MCC will incorporate its marketing through the industrial gas sales network of TNSC’s wholly owned U.S. subsidiary, Matheson Tri-Gas, Inc. (Head office: New Jersey, the U.S.)

(2) Proposals for hybrid dehydration process

MCC will develop proposals for customers to optimize their energy-saving processes and increase production by combining MZM’s A-type zeolite membranes and MCC’s CHA-type zeolite membranes.

The PSA dehydration process, which is currently adopted in many bioethanol plants, uses pellet-form general-purpose zeolite to absorb water. PSA’s zeolite beds use a absorption-desorption cycle every several minutes and must recycle about 20% of the refined bioethanol. Its vapor phase operation and continual recycling make the process very energy intensive.

The ZEBREXTM dehydration system combines CHA-type zeolite membranes, which have high separation performance with high water content, and A-type zeolite membranes, which are highly effective in final dehydration. This zeolite membrane system does not require recycling, so ethanol producers can reduce energy costs and increase production up to 15% by replacing the PSA process with the ZEBREXTM dehydration system or by adding ZEBREXTM dehydration system to their current process.

For further information, please contact:

Public Relations and Investor Relations Office

Mitsubishi Chemical Holdings Corporation

Tel: [+81] (0)3-6748-7140

Public Relations Section

Corporate Planning Department

Mitsui Shipbuilding & Engineering Co., Ltd.

TEL: [+81] (0)3-3544-3147

[Company profile of MZM]

|

Company name: |

Mitsui Zosen Machinery & Service, Inc.

|

|

Representative: |

Masao Morita

|

|

Head office location: |

7 Kanda Kon-ya-cho, Chiyoda-ku, Tokyo

|

|

Business establishment: |

Tokyo (Akishima) Works, Osaka Works

Office: Sapporo, Tokyo, Yaizu, Nagoya, Osaka, Fukuoka

|

|

Capital: |

470 million yen

|

|

Net sales: |

6,783 million yen

|

|

Product and service: |

Customized engines for construction equipment and special application vehicles, Land gen-set with air-cooled engines, Land gen-set with water-cooled engines, Marine gen-set with air-cooled or water-cooled engines, Special applications for air-cooled engines, Pump-drive diesel engine sets, Zeolite membrane dehydration units, MITUSI-MARCO hydraulic deck machinery system, Factory automation, Cooling unit and refrigerators, Dehumidifiers, Steam turbine generator

|

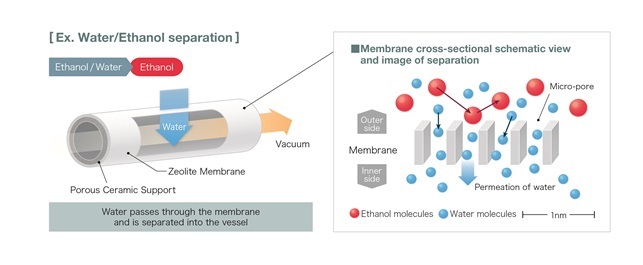

[Dehydration process using zeolite membranes]

[Outline of ZEBREXTM dehydration system]

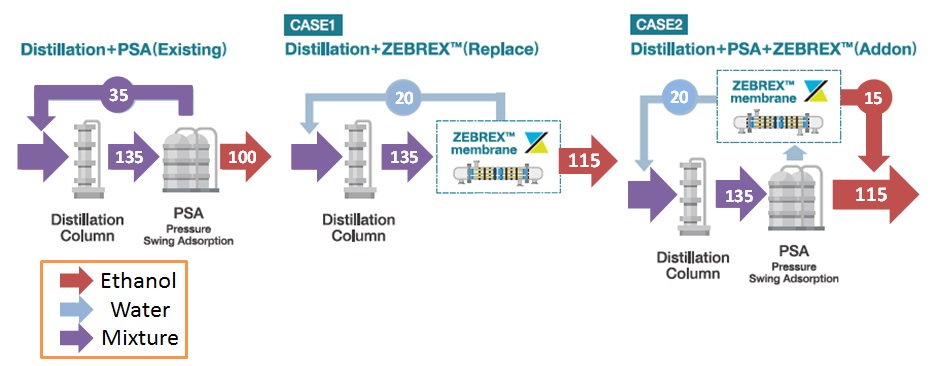

Current CASE1 CASE2

(Current)

Bioethanol generated by fermentation is dehydrated using the PSA process after refining in the distillation column. The recycling step of the PSA process consumes about 20% of the refined bioethanol.

(CASE1)

The current PSA process is replaced with the ZEBREXTM dehydration system. Unlike the PSA process, this does not require the recycling step. Compared to the current process, it is expected to increase production by about 15%.

(CASE2)

The ZEBREXTM dehydration system is added to the current dehydration process. It is expected to increase production about by 15%, by dehydrating high water content ethanol, which is generated in the recycling step of the PSA process.

|

|

|

|

|

|