Building a Circular Economy with the Aim of Sustainable Growth

Mitsubishi Chemical Corporation

Relevant SDG

SDG 13: Take urgent action to combat climate change and its impacts

Offering New Business Solutions by Pursuing a Circular Economy

The world today faces numerous serious challenges, such as climate change and various problems arising from population growth. Chemical technologies have tremendous potential to solve a wide range of social issues. Mitsubishi Chemical (MCC), as a member of society and as an integrated chemical company, has long faced such issues head-on.

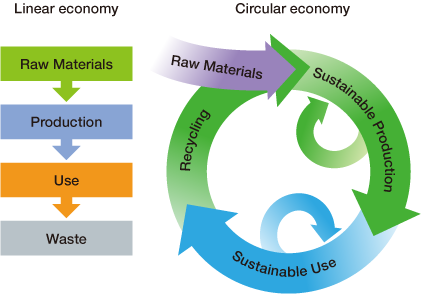

Particularly in recent years, demand from customers for sustainable products has been growing constantly in response to tightening environmental regulations in various countries. MCC aims to meet the demands of society while achieving sustainable growth by transitioning from a traditional one-way linear economy of “take-make-waste” to a circular economy (CE) based on the effective use of resources, including recycling, and the use of renewable raw materials.

Below, we highlight some of the concrete steps we are taking, such as the establishment of a division dedicated to the promotion of a CE and the implementation of initiatives to tackle the issues of plastic waste and climate change.

Offering Solutions from a Global Perspective in Collaboration with Value Chain Partners

In April 2020, MCC established the Circular Economy Department (changed to the Circular Economy Division as part of organizational reforms in April 2021; hereinafter, the “CE Division”) to reinforce initiatives that address social issues related to sustainability. While work in each business domain to solve sustainability-related issues is ongoing, the CE Division operates from a global perspective and scale across business domains and with value chain partners to pursue CE-related solutions and develop them into businesses. The division will also actively promote collaborations with such business partners as academia and start-ups.

The CE Division handles CE-related issues on a company-wide basis. The division’s activities include identifying CE-related issues and formulating strategies at the company-wide level, promoting the development of solutions into businesses and implementing sustainability management to reduce the impact on the environment of our business activities, including greenhouse gases (GHGs) and wastewater emissions. In addition, the division will gather and provide information on sustainability-related policy in various countries and support dialogue about CE between related departments and customers.

Advancing Partnerships to Build a Plastic Recycling Scheme

Recycling is extremely important to the transition from a linear economy to a circular economy.

Plastic recycling is broadly divided into two approaches: (1) mechanical recycling, in which collected used plastic is melted down and remolded for reuse, and (2) chemical recycling, in which it is decomposed into monomers or intermediate materials for repolymerization or broken down into oil or gas for use as a raw material in chemical production. MCC is advancing partnerships with a variety of partners that include technology development based on both approaches. In doing so, we are reinforcing efforts to build a scheme for recycling plastic waste —which have conventionally been simply incinerated or buried in landfills—into resources and raw materials. Featured below are some of the chemical recycling initiatives we are implementing in collaboration with value chain partners.

Plastic-to-Oil Conversion

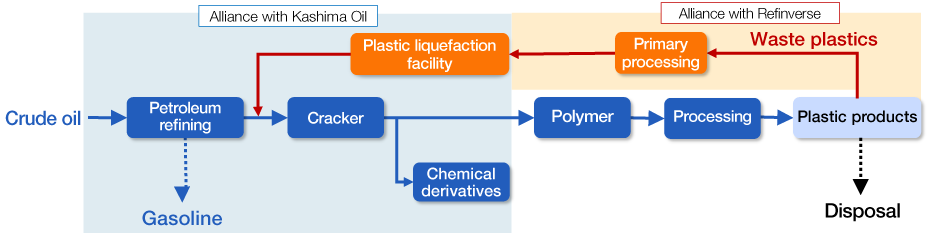

MCC and ENEOS Corporation jointly established Kashima Complex LLP in 2019. Through this partnership, the companies are working toward the commercialization of the chemical recycling of plastic waste. Specifically, the two companies are constructing a plastic-to-oil conversion facility at MCC’s Ibaraki Plant. The facility will commence operation in 2023 with an annual processing capacity of 20,000 tons, the largest of its kind in Japan. The conversion process at the facility will be carried out with supercritical water treatment technology from U.K.-based Mura Technology Limited. The recycled oil produced will be used as a raw material in existing oil refineries and naphtha crackers owned by ENEOS and MCC. It will be converted to petroleum products, chemicals and various plastic products, and, in this way, the two companies aim to realize highly efficient chemical recycling. In addition, the procurement of raw material plastic waste will be carried out in collaboration with Refinverse, Inc., with which MCC formed a capital and business alliance in August 2020.

Chemical Recycling of Acrylic Resin

MCC and Mitsubishi Chemical Methacrylates Ltd. have for some time been investigating the recycling of polymethyl methacrylate (PMMA, or acrylic resin). In Europe, we are studying methods of recycling using existing technologies. In Japan, we constructed a new demonstration facility within the Osaka site of Microwave Chemical Co., Ltd., our partner for acrylic resin recycling technology study, in June 2021. Tentatively aiming to begin operations in 2024 in Europe and Japan based on these respective approaches, we are accelerating work toward the construction of acrylic resin recycling plants.

Acrylic resin is a plastic product with excellent transparency and light resistance used for a wide range of applications, including vehicle lamp covers, sign boards, aquarium water tanks, paints and construction materials. In particular, since the start of the COVID-19 pandemic, demand for acrylic resin sheets used for protection against droplet infection has increased. Going forward, we are considering sourcing acrylic resin for recycling not only from waste generated by our plants, but from a broader market. As part of these efforts, we have partnered with Honda Motor Co., Ltd. to jointly implement demonstration testing of systems for the chemical recycling and reuse of acrylic resin collected from the taillights and other parts of end-of-life vehicles.

Reducing GHGs through an Artificial Photosynthesis Project

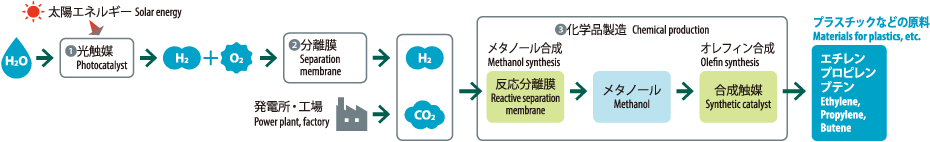

Artificial photosynthesis is a promising approach to reducing GHGs that uses CO2 emitted from power plants and factories as a raw material for chemical products. Since 2012, MCC has participated as a member of ARPChem,*1 a NEDO*2 project aimed at realizing artificial photosynthesis, and is involved in the development of core technologies for all of the following three processes.

1. A photocatalyst splits water into gaseous hydrogen and oxygen; 2. the hydrogen is then safely separated out of the mixed hydrogen and oxygen gas using a separation membrane; and 3. the hydrogen is used as a raw material together with CO2 recovered from the gas emissions of power plants or factories to produce chemical products.

The project’s target for photocatalyst solar energy conversion efficiency has been set at 10%. In fiscal 2019, an efficiency of 7% was achieved in a laboratory setting. Outdoor demonstrations of the water splitting systems began in fiscal 2020.

- *1ARPChem: Japan Technological Research Association of Artificial Photosynthetic Chemical Process, comprising INPEX CORPORATION, TOTO LTD., Japan Fine Ceramics Center, Fujifilm Corporation, Mitsui Chemicals, Inc., and MCC.

- *2NEDO: New Energy and Industrial Technology Development Organization

Establishing a Long-term Vision for the Chemical Industry

MCC and the Center for Global Commons (CGC) at the University of Tokyo have formed an industry-academia partnership with the aim of formulating a long-term vision of the chemical industry’s approach to sustainability with an eye toward society in 2050.

To ensure the sustainability of global environmental systems, CGC aims to scientifically demonstrate pathways for the fundamental transformation of socio-economic systems based on modelling and indices. In collaboration with a wide range of stakeholders, including private enterprises, CGC aims to drive this fundamental transformation through international cooperation.

MCC and CGC began joint research on April 1, 2021 to identify the social needs (particularly in the areas of products, services and social systems) of 2050, as well as those expected to emerge along the way by 2030 and 2040, and, given such needs, the role the chemical industry must play in protecting the Global Commons.*3

Specifically, we will outline a vision for the chemical industry that encompasses reducing the environmental impact of the chemical industry itself as well as the role it must play and issues it must solve in relation to other industries and consumers in order to achieve socio-economic sustainability within the Planetary Boundaries.*4 In particular, we are researching ways that the chemical industry can contribute to the transition of key economic systems in such areas as production and consumption, energy, food and cities. By bringing together outside expertise and knowledge, this research is able to gain insights from the latest initiatives in Europe and elsewhere in the world to build and utilize quantitative models for key chemical products, from their raw materials to their recycling or disposal, and thereby elucidate the path forward for Japan’s chemical industry. The results of this research will be broadly shared with society to accelerate the realization of socio-economic sustainability.

- *3Global Commons: The global environmental system upon which the sustainable development of humankind is founded.

- *4Planetary Boundaries: The nine processes that stabilize the global environmental system (climate change, biodiversity, nitrogen and phosphorus cycles, etc.), in which thresholds that must not be crossed for humanity to develop sustainably are defined. Crossing these thresholds increases the risk of large-scale and irreversible environmental change. Climate change is in the uncertainty zone, and the biodiversity and nitrogen and phosphorus cycles are considered to have crossed the thresholds.