Structural Repair and Strengthening Carbon Fiber Fabric REPLARK™

Mitsubishi Chemical Corporation

Relevant SDG

SDG 11: Make cities inclusive, safe, resilient and sustainable

Targeting Sustainable Infrastructure

Recent years have seen numerous heavy rains, earthquakes, volcanic eruptions, tsunamis, droughts and other natural disasters around the world. Typhoons, heavy rains, and the subsequent flooding are becoming more frequent and more severe, and damage from earthquakes is unending. In addition to the harm they inflict in terms of human life, the economic toll of such disasters is a major barrier to the realization of a sustainable society. Natural disasters significantly impact highly developed countries and, in countries where infrastructure is underdeveloped, can wreak even greater harm.

As bridges, expressways, tunnels and other such infrastructure components age, their safety becomes harder to ensure; incidents involving collapsing or failing infrastructure in and outside Japan have been occurring one after another. Furthermore, the decreased utility of aging structures and the expense of repairing and strengthening them are major social issues.

The Mitsubishi Chemical (MCC) and its group companies provides a range of products and services that aid in addressing the critical state of infrastructure and contribute greatly to the realization of the SDG “Make cities inclusive, safe, resilient and sustainable.” One such product is the structural repair and reinforcement carbon fiber fabric REPLARK™ offered by Mitsubishi Chemical Infratec Co., Ltd.

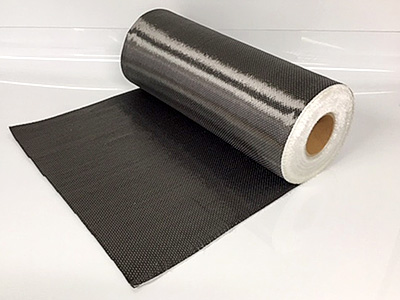

Features of REPLARK™

Carbon fiber boasts many advantageous features: It has a specific gravity just 1/4 that of iron, yet approximately 10 times the strength of steel, and it is highly chemically stable, making it resistant to salt damage. REPLARK™ is a repair and reinforcement material made of unidirectional carbon fiber for steel and concrete structures. As a fabric, REPLARK™ can be applied to structures of various shapes and offers excellent workability. The grade of REPLARK™ made with PAN-based carbon fibers can be used to enhance the load bearing capacity of such structures as bridge columns, while the high-elastic-modulus grade made with pitch-based carbon fibers can greatly reduce rebar stress. In addition to REPLARK™ fabric, we offer a range of formed carbon-fiber reinforced polymer (CFRP) products, such as e-Plate (strips) or LEADLINE™ (rods), to meet the needs associated with various applications.

Applications of REPLARK™

REPLARK™ provides the following functions when used with existing structures.

- It reinforces bridge girders against bending and enhances the fatigue durability of bridge deck slabs

- It improves the seismic resistance of bridge columns and other structures by absorbing energy from earthquakes

- It prevents concrete stripping from tunnel surfaces

In addition to offering the lightness, strength and elasticity of carbon fiber, REPLARK™ is simple to install; fabric impregnated with epoxy resin need only be applied to the structure surface. As such, it offers the following advantages for repairing and strengthening structures.

- Because it is lightweight and simple to install, carrying and handling the necessary materials at the worksite is easy

- It enables repairs in tight spaces where maneuvering and installing steel components is difficult

- It adds almost no weight to the structure being repaired or strengthened, helping reduce the load on the existing structure

The development of REPLARK™ goes back to the 1980s. Recognition of the need for such a product and its usefulness has gradually increased, and today it is starting to be used not only in Japan, but also in Southeast Asia and Europe.

Installation on Genta Bridge

Genta Bridge, located in Tottori City, Tottori, was completed in 1951. While in relatively good repair, the bridge was narrow, making passage difficult for large vehicles, and its load capacity was no longer sufficient due to the increasing size of vehicles on the road.

To address these issues, Tottori Prefecture sought to broaden and strengthen the bridge, but doing so by conventional methods would significantly increase the bridge’s weight, requiring large-scale construction. Instead, the bridge’s reinforced concrete girders were replaced with steel; external cables and REPLARK™ carbon fiber fabric were used for strengthening; and LEADLINE™ carbon fiber rods were used to strengthen the deck slabs. As a result, the overall cost was approximately halved from what it would have been using conventional construction methods. In recognition of these achievements, the bridge received the Japan Society of Civil Engineers 2014 Tanaka award.

Test of Bridge Deck Slab Strengthening Using e-Plate

In recent years, to save on-site labor, the use of e-Plate carbon fiber-reinforced plastic strips (carbon fiber yarn processed into strips at a plant) to strengthen deck slabs has been increasing. This construction method entails bonding e-Plate strips that have been impregnated with epoxy resin at a plant to the underside of deck slabs. Unlike deck slab underside reinforcement using REPLARK™, this method does not cover the entire underside of the slab, leaving the concrete visible, which makes it easier to observe the condition of the slab after reinforcement. The Public Works Research Institute’s Civil Engineering Research Institute for Cold Region (based in Hokkaido) carried out a wheel load running test on slabs reinforced with this method and found that fatigue durability showed a more than tenfold improvement compared with unreinforced slabs.

Working toward the SDGs

As expressed by the SDG “Make cities inclusive, safe, resilient and sustainable,” building safe, reliable infrastructure is among the most important tasks we face. However, securing the funding and manpower needed to renovate infrastructure remains difficult. The MCC Group strives to find solutions to these two difficult and conflicting issues through innovation and global business development.